Cable Manufacturing

CABLE MANUFACTURING TECHNOLOGY:

INSULATION

CONSTRUCTION

COLOR CODING

ACCURACY

SPECIALS & CABLE HARNESS ASSEMBLIES

We offer a wide variety of cable solutions for Thermocouple , RTD and General Instrumentation and Automation Requirements. We can offer different permutations and combinations in the construction of the cable with help and support from our established network of vendors.

INSULATION :

Cables are available with various types of Insulations to meet specific requirements, viz. High Abrasion Resistance, Moisture Impermeability, Temperature Resistance, Resistance against Chemical attack, etc. Our standard product capability

Several advanced technology insulated cables like PEEK , ETFE, SPEC55 etc. are also available for specific property applications. We can source such cables , if required for your sensor assembly.

We can offer composite insulations i.e inner core of PTFE ( Teflon) and Outer Jacket of Silicone Rubber or FEP.

Properties of Insulating and Jacketing Materials

INSULATION

CONSTRUCTION

COLOR CODING

ACCURACY

SPECIALS & CABLE HARNESS ASSEMBLIES

We offer a wide variety of cable solutions for Thermocouple , RTD and General Instrumentation and Automation Requirements. We can offer different permutations and combinations in the construction of the cable with help and support from our established network of vendors.

INSULATION :

Cables are available with various types of Insulations to meet specific requirements, viz. High Abrasion Resistance, Moisture Impermeability, Temperature Resistance, Resistance against Chemical attack, etc. Our standard product capability

- PVC, Polyethylene, Nylon, etc. with standard properties for general application.

- Special Grade Plastics viz. Flame Retardant Low Smoke( FRLS), Heat Resistant (HR), Rodent Protected etc. for hazardous locations.

- Fibreglass & Ceramic Braided Cables for High Temperature Usage

- PTFE ( Teflon) Tape Wrapped Cables and FEP Extruded Cables

- Silicon Rubber for high flexibility applications etc.

- Kapton ( Polyamide) Tape Wrapped and Sintered Cables for Aerospace Applications

Several advanced technology insulated cables like PEEK , ETFE, SPEC55 etc. are also available for specific property applications. We can source such cables , if required for your sensor assembly.

We can offer composite insulations i.e inner core of PTFE ( Teflon) and Outer Jacket of Silicone Rubber or FEP.

Properties of Insulating and Jacketing Materials

| Material Type | Continuous Operating Temperature | Abrasion Resistance | Chemical Resistance | Moisture Resistance | Solvent Resistance | Flame Resistance |

| PE | 176°F (80°C) | Good | Excellent | Excellent | Excellent | Poor |

| CPE | 194°F (90°C) | Very Good | Excellent | Excellent | Excellent | Excellent |

| PVC | 221°F (105°C) | Very Good | Very Good | Good | Fair | Excellent |

| TPE | 257°F (125°C) | Excellent | Poor | Good | Good | Excellent |

| Nylon | 250°F (121°C) | Excellent | Very Good | Fair | Good | Poor |

| ETFE | 300°F (150°C) | Excellent | Excellent | Excellent | Excellent | Excellent |

| FEP | 400°F (200°C) | Excellent | Excellent | Excellent | Excellent | Excellent |

| TE/D | 400°F (200°C) | Excellent | Excellent | Excellent | Excellent | Excellent |

| PFA | 500°F (260°C) | Excellent | Excellent | Excellent | Excellent | Excellent |

| PTFE | 500°F (260°C) | Good | Excellent | Excellent | Excellent | Excellent |

| Polyimide | 500°F (260°C) | Excellent | Excellent | Excellent | Good | Good |

| B-Fiber* | 500°F (260°C) | Good | Good | Fair | Good | Good |

| G-Glass* | 950°F (510°C) | Poor | Good | Good | Excellent | Excellent |

| Q-Glass* | 1300°F (704°C) | Fair | Good | Good | Excellent | Excellent |

| HG | 1800°F (982°C) | Poor | Good | Poor | Excellent | Excellent |

| CEFIR™ | 2200°F (1204°C) | Fair | Good | Fair | Excellent | Excellent |

*Performance characteristics of fibrous products are improved with impregnation. Impregnation maintained to (180°C).

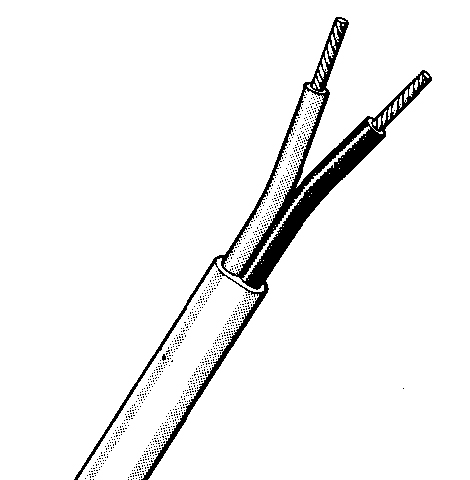

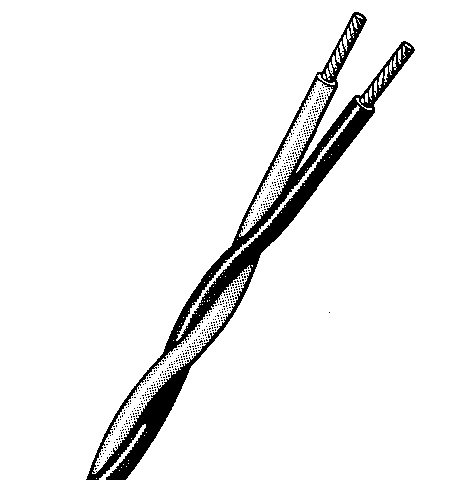

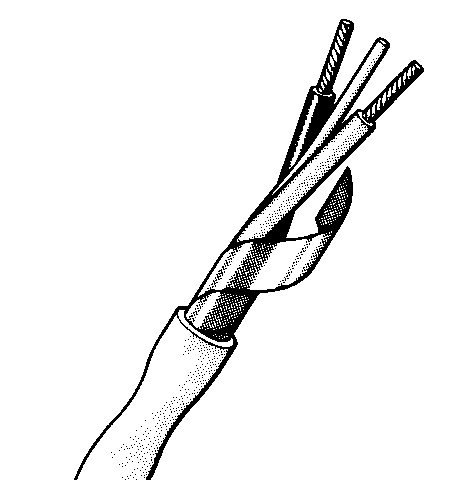

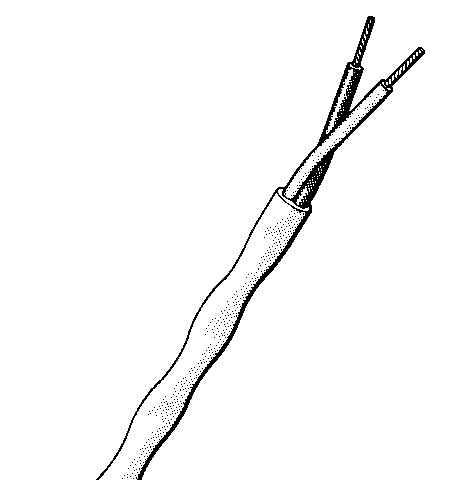

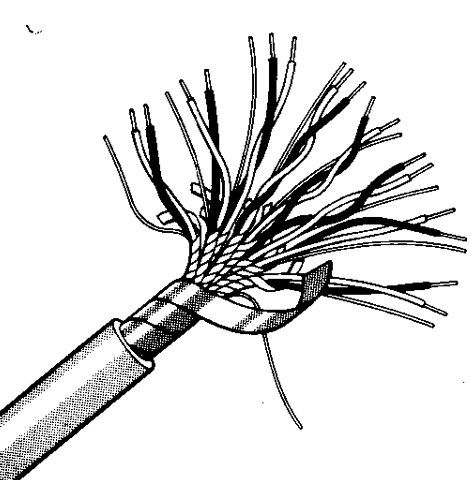

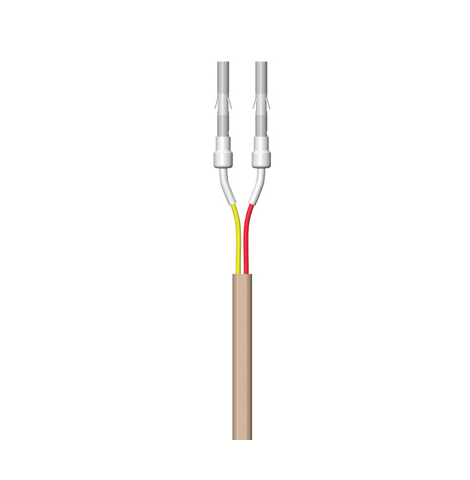

CONSTRUCTION OF CABLES :

Cables can be offered with

Cables can be offered with

- Solid ,Stranded or Bunched Conductor Construction

- Single Cores

- Flat Twin

- Twisted Pairs

- Multi-Pairs (2– 24 Core).

- Aluminium / Polyester Screens

- Tinned, Silver or Nickel plated Copper Braided Screens

- Armoring of Cable

- Overbraid of Stainless Steel

- Silver Plated ( SPC ) , Nickel Plated and Tin Plated Copper Conductors for RTD Cables.

- Thermocouple Conductor – Thermocouple Alloy Grade , Extension Grade OR Compensating Grade

- Accuracy : Class I or Class II accuracy for Thermocouple Conductors

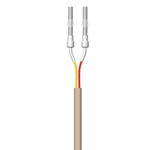

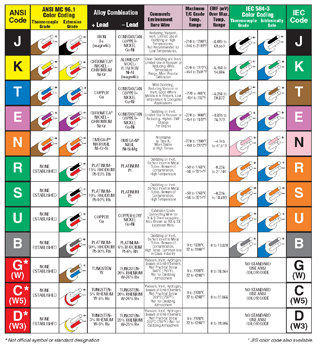

COLOR CODING

For Thermocouples : As per ASTM , IEC , DIN , GOST , IS , British Standards. For RTD : Inner Core : Red and White , Outer Jacket : Grey

Apart from the above any user specified color coding can also be offered provided MOQ Requirements are met.

For Thermocouples : As per ASTM , IEC , DIN , GOST , IS , British Standards. For RTD : Inner Core : Red and White , Outer Jacket : Grey

Apart from the above any user specified color coding can also be offered provided MOQ Requirements are met.

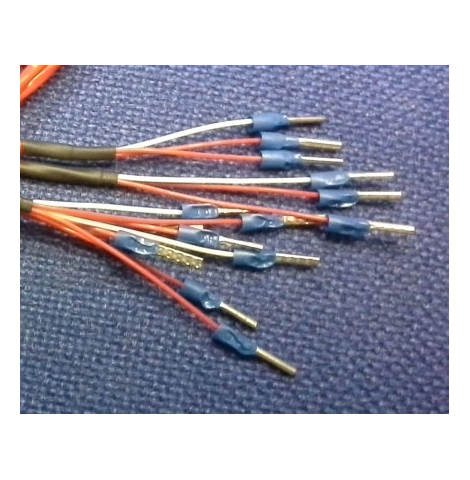

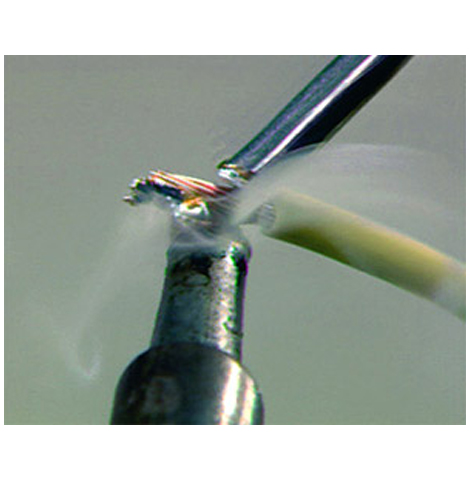

SPECIALS : CABLE HARNESS ASSEMBLIES

We can provide for some special cable harness assemblies , with cables cut to length , Stripped , Soldered , Crimped , Moulded on Connector , Soldered Connector and many more operations. We have necessary crimping tools , dies , fixtures etc. necessary to carry to such custom harnessing detail. Details of some specials for your ready reference provided below.